Why choose

Thorlux Lighting is a globally recognised manufacturer of luminaires and lighting control systems.

Headquartered in Worcestershire, UK, its modern 16,882 m² factory is just a few miles from where Frederick William Thorpe first manufactured Thorlux luminaires in 1936. Thorlux still proudly manufactures over 90% of its products in the Midlands.

Thorlux is a complete lighting solutions partner, a single point of contact for luminaires, controls, design, installation, and more. Sustainability and environmental care are written in the organisation’s DNA, with a 2040 net-zero greenhouse gas emissions target.

Download BrochureSolutions for all applications.

Car parks, clean environments, custodial, data centres, education, external, food processing, hazardous areas, healthcare, industrial, office, railways, social housing, retail, warehousing, and logistics.

Thorlux history

A family matter.

Frederick William Thorpe founded Thorlux Lighting in Small Heath, Birmingham, in 1936. The company flourished and moved to progressively larger and larger premises in the city - first to Hall Green in 1939, then to Kings Norton in 1963.

Frederick Thorpe’s son, Ernest, became company chair in 1981. Under his stewardship, Thorlux moved to its present headquarters in Redditch, Worcestershire, in 1989. Andrew Thorpe, FW Thorpe’s grandson, was chair from 2003 to 2017.

Today, Thorlux and the FW Thorpe Group stand as one of the largest lighting system manufacturers in the UK, with over nine hundred employees globally. The Thorpe family remains closely involved in the day-to-day running of the business, with James Thorpe, great-grandson of the founder, serving as Joint Managing Director of Thorlux Lighting.

As the company approaches its 90th anniversary in 2026, it continues to build on a proud legacy of innovation, quality, and family stewardship.

Why choose Thorlux?

Reliability you can depend on.

Five year warranty

A genuine warranty with genuine value.

The Thorlux range of luminaires is designed, manufactured and distributed by Thorlux, a division of the FW Thorpe Plc group. FW Thorpe Plc is listed on the London Stock Exchange. See the corporate website at www.fwthorpe.co.uk.

Thorlux luminaires have been continuously manufactured in the UK since 1936, when Frederick William Thorpe founded the company.

In 2023-24, the revenue of FW Thorpe Plc was £175.8m, of which £91.8m was generated by Thorlux luminaires and control systems.

The Thorlux product warranty offered to customers covers a period of five years, with no get-out clauses concerning the number of burning hours or maintenance requirements, and no convoluted registration process.

Thorlux Warranty PDFThis warranty is enhanced by the following key factors:

- FW Thorpe Plc has a robust balance sheet, with net assets exceeding £175m (2024)

- Over £50m in cash reserves means Thorlux can support any future warranty liabilities and is resilient against supply chain shocks

- FW Thorpe Plc has a stable ownership structure, with over 50% of the business owned by founding family members and management

- Investment in product research and development is continual - £2m invested per annum

- Thorlux product failure rates are consistently below 0.2%, with over 2,000 luminaires individually tested and shipped every day

- Critical components from market-leading global suppliers

- A dedicated team of our own employed local service engineers respond to any customer issues quickly and effectively, not only in the UK but overseas too

- Around 90% of Thorlux products are manufactured in the UK, therefore spares are readily available

- Audited by PricewaterhouseCoopers LLP (PwC)

Please refer to www.thorlux.co.uk/terms for full details of our terms and conditions of sale.

Lighting a greener tomorrow

On a journey to net-zero by 2040.

For the last two decades, Thorlux Lighting, as part of the FW Thorpe Plc Group, has worked hard to reduce its environmental impact, and we are proud of the progress made.

But, recognising that there is still much to do to safeguard the environment and avoid the worst effects of climate change, Thorlux and the FW Thorpe Plc Group have set a target to reach net-zero greenhouse gas (GHG) emissions by 2040, ten years before the UK government’s 2050 net-zero target.

Learn moreA validated net-zero target

FW Thorpe Plc has committed to reaching net-zero greenhouse gas emissions across the value chain by 2040.

The Science Based Targets initiative (SBTi) has validated these science-aligned targets:

Near-term target

FW Thorpe Plc commits to reducing absolute scope 1 and 2 GHG emissions by 57.5% by FY2030 from a FY2021 base year. FW Thorpe Plc also commits to reducing absolute scope 3 GHG emissions by 25% within the same timeframe.

Long-term target

FW Thorpe Plc commits to reducing absolute scope 1 and 2 GHG emissions by 90% by FY2040 from a FY2021 base year. FW Thorpe Plc also commits to reducing absolute scope 3 GHG emissions by 90% within the same timeframe.

Thorlux Lighting has been carbon neutral since 2012 through a combination of measures. Company-wide initiatives such as energy use minimisation, self-generation through solar photovoltaic (PV) units, and renewable energy procurement have reduced Thorlux’s carbon footprint, whilst trees in our award-winning carbon offsetting afforestation project sequester the remaining carbon dioxide produced. Our carbon-neutral status is independently verified as per ISO 14064-1.

Thorlux carbon offsetting project

Since 2009, Thorlux has developed a carbon-capture woodland at Devauden, Wales, in a scheme certified to ISO 14064-3 and ISO 14065 standards. Thorlux has planted 179,412 native broad-leaf trees, offsetting more than 44,385 tonnes of CO₂e emissions over 100 years.

With the Devauden woodland now complete, Thorlux has purchased 195 acres at Brook Farm in Herefordshire. This land has significant potential for connecting existing woodlands to enhance biodiversity. Methods such as leaky dams will reduce flooding by holding water in the landscape.

Thorlux is committed to making this a destination for community enjoyment. By establishing a network of shale paths, dog walkers and visitors will have easy access via a public right of way from the village or a car park at the entrance. Signposts, waymarkers, noticeboards, benches and picnic areas will enhance the visitor experience.

Learn moreThe Woodland Carbon Code is a voluntary standard for woodland creation projects in the UK to monitor and assess CO₂ claims. See woodlandcarboncode.org.uk.

Lighting control systems

Leading the way in intelligent lighting innovations.

Since developing its first eco controls in the mid-1990s, Thorlux has led the field in lighting control innovations. Intelligent IoT lighting controls provide numerous advantages, including reduced energy consumption, extended luminaire lifespan, automated emergency testing, targeted maintenance and more.

Intelligent lighting, intelligent savings.

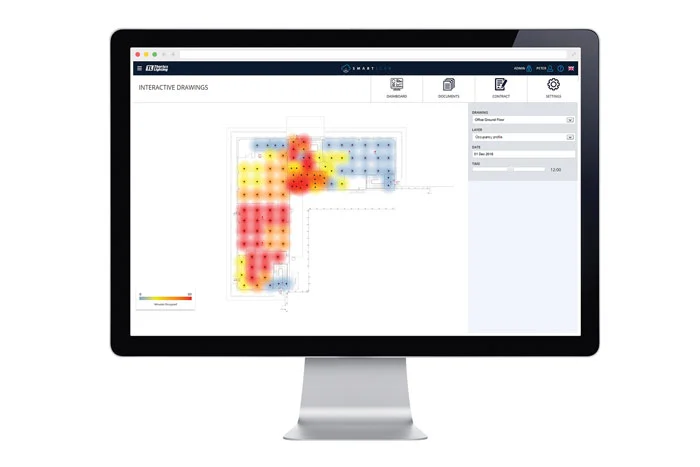

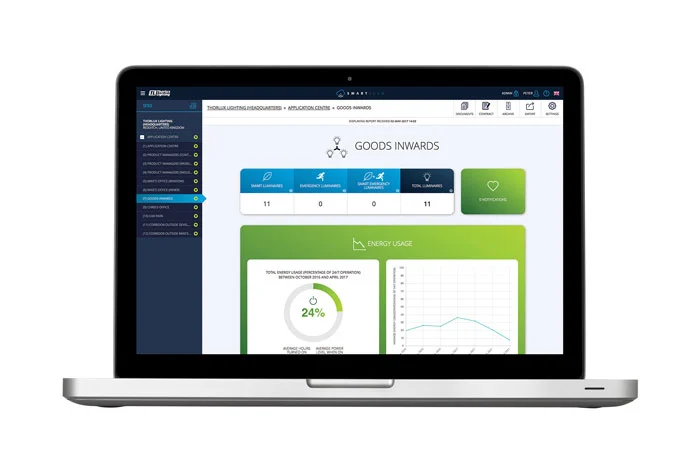

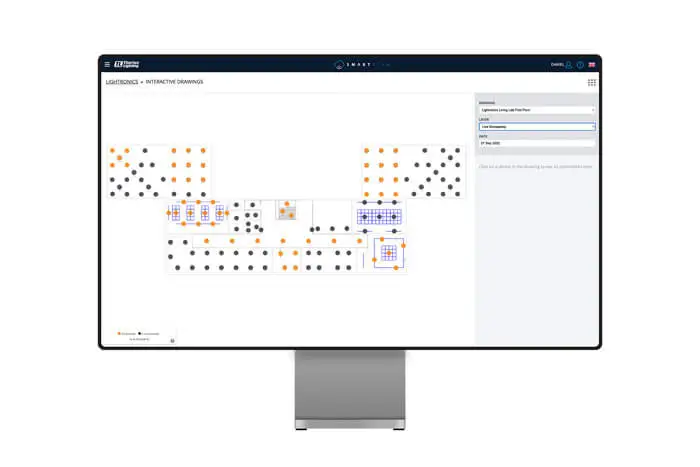

SmartScan is a revolutionary wireless lighting management system that maximises energy savings and automates emergency lighting testing and record keeping. Users can monitor their energy performance data and complete operational information for all SmartScan standard and emergency luminaires.

Users can access the online SmartScan platform from any web-connected device. The clear graphical user interface provides an overview of the whole site down to the performance of an individual luminaire. Data can also be accessed via API.

Learn more

Over 700,000*

connected SmartScan devices worldwide.

* April 2025

WIRELESS LIGHTING MANAGEMENT SYSTEM

The SmartScan lighting management system makes the most of maintained illuminance, daylight dimming and presence detection to ensure optimum energy savings, often measured in real applications to exceed 80%. SmartScan also monitors the performance of all luminaires so any fault can be reported promptly to the maintenance teams.

SmartScan features

one

- One manufacturer.

- One team.

- One contact.

Thorlux Lighting knows managing a lighting system installation or refurbishment project is complicated and demanding.

For this reason, we offer Thorlux One, a complete, full-life solution for new and refurbished lighting system projects. Thorlux provides a professional one-stop-shop service that takes all the work out of your hands, from planning to installation and beyond.

Thorlux product testing

Quality testing, guaranteed performance.

Rigorous product testing is essential in maintaining a reputation for reliability and quality.

The Thorlux Lighting Industry Association (LIA)-certified photometric laboratory enables the company to obtain the best optical performance from its luminaires. In addition, customers can be sure that the photometric data provided by Thorlux is accurate.

A sophisticated goniophotometer in the photometric test laboratory gives fast and reliable measurements of a luminaire’s light distribution. An integrating sphere equipped with a spectral analyser accurately measures light quality, efficiency and colour temperature.

Other in-house testing covers environmental and electrical parameters, including extreme ambient temperatures, dust/water ingress, electromagnetic compatibility and current harmonics, per relevant British and European standards.

All test equipment is subject to regular in-house maintenance and calibration, with external third-party calibration at regular intervals to ensure data accuracy.

Investing for the future

Driving innovation through strategic investment.

Thorlux has made multi-million-pound investments in increasing capacity, reducing energy consumption, and modernising its manufacturing processes.

Thorlux has installed high-tech automated metal punching and laser cutting machines, incorporating the latest fibre laser technology. The machines can run several jobs of different material types, making it easier to produce smaller batch sizes and fulfil more orders faster.

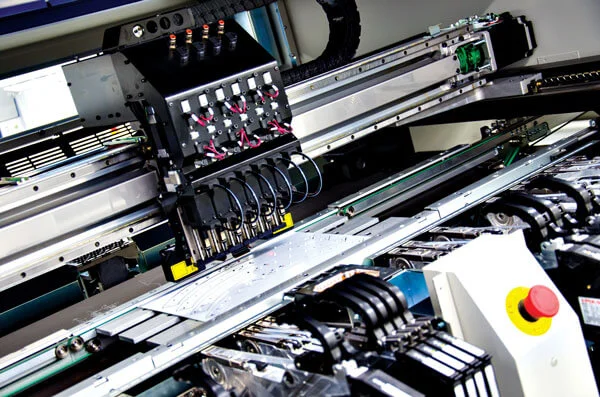

Following extensive investment in an in-house electronic component assembly cleanroom facility, Thorlux designs, manufactures, and tests its LED electronic systems (including lenses) on-site for precise optical control. Up to 600,000 components can be placed each day.

Thorlux is a significant consumer of electrical cable, using an average of 1.8 million metres each year. To reduce its environmental impact, Thorlux is switching to cables manufactured from low-carbon 8mm copper rod, which generates less 62% less CO₂ per kilo than standard copper. Thorlux anticipates a reduction of 27.5 tonnes in CO₂ emissions annually.

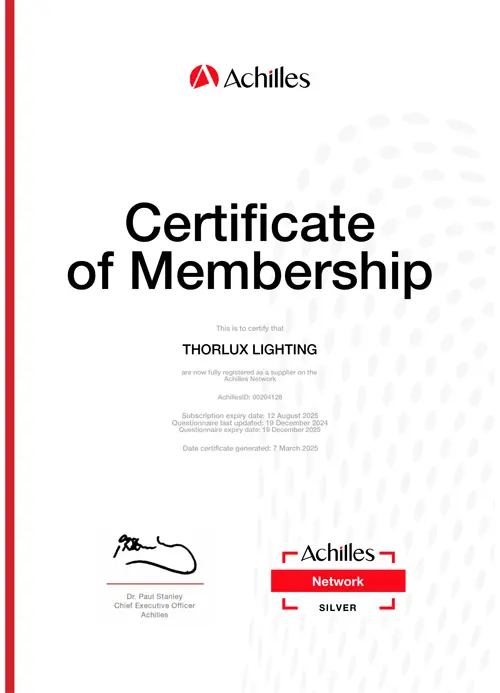

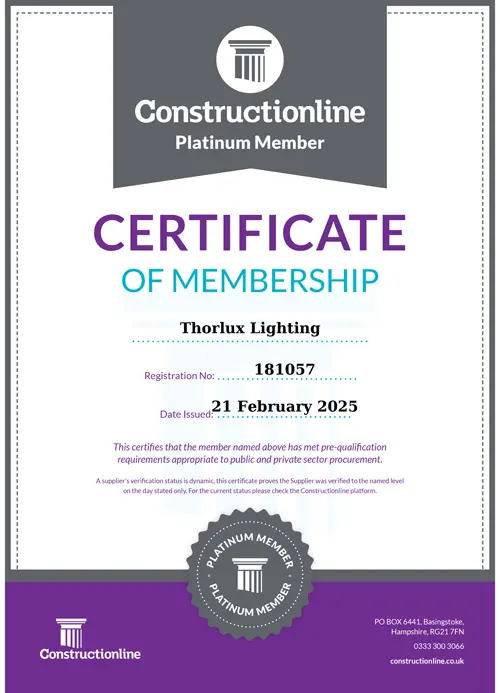

Thorlux company certification

Quality you can trust.

Retrofit/bespoke solutions

Personalised lighting solutions.

Retrofitting can also be an economically effective way of modernising an outdated lighting system while reducing waste and improving product circularity.

Retrofitting a lighting system with energy-efficient LEDs cuts greenhouse gas emissions, reduces waste, and can also improve visibility, comfort, and light quality. Further benefits include lower maintenance requirements, longer lifespan and improved durability. Integrating intelligent lighting controls results in efficient usage management, further reducing energy consumption.

Thorlux Lighting offers a complete retrofitting service to convert existing non-LED light fittings or upgrade older LED luminaires to the latest energy-saving technology. Thorlux has a long history of providing retrofit and custom lighting solutions; its flexibility, experience and in-house manufacturing enable its engineers to implement lighting solutions that balance environmental, aesthetic, and economic considerations.

Complete retrofit solution at Aston University Library, Birmingham, United Kingdom

More DetailsBefore

During

Thorlux declarations of conformity

Ensuring safety, functionality, and quality.

Thorlux manufactures its products to the most stringent quality control standards in the most environmentally friendly manner.

Declarations of Conformity are available that state Thorlux has tested its luminaires to comply with the relevant international standards for manufacturing luminaires and related products.

The standards used are:

| EN 55015 | Limits and measurement of radio disturbance |

| EN 61547 | Electromagnetic compatibility immunity requirements |

| EN 61000-3-2 | Limits for harmonic current emissions |

| EN 60598-1 | Luminaires: general requirements and tests |

| EN 60598-2-1 | Fixed general-purpose luminaires |

| EN 60598-2-22 | Luminaires for emergency lighting |

Each declaration also confirms that products are manufactured to an approved ISO 9001 quality system and tested before despatch. Tests include those for safety earth circuit continuity, high voltage electrical strength, full circuit functionality including dimming, and current drawn. Specialist in-house protection circuitry is employed to prevent damage to equipment under test conditions.

Certification to ISO 9001 and ISO 14001, coupled with the in-house testing to British and European standards, clearly demonstrate that Thorlux cares about the quality of its products and the environment.

How to specify your lighting supplier

Key considerations for your lighting partner.

- The supplier shall be committed to high levels of quality control and performance, as proven by independent assessment and certification to ISO 9001 (Quality Management Systems).

- The supplier shall be responsible for its environmental activities and demonstrate genuine concern, as proven by independent assessment and certification to ISO 14001 (Environmental Management Systems).

- The supplier shall prioritise the welfare of the workforce and site visitors, as proven by independent assessment and certification to ISO 45001 (Occupational Health and Safety Management Systems).

- The supplier shall prioritise the protection of sensitive data, as proven by independent assessment and certification to ISO 27001 (Information Security).

- The supplier shall provide Certificates of Conformity proving compliance with European legislation directives 2006/95/EC, 2004/108/EC and 2011/65/EU.

- Photometric test information shall be available using independently assessed equipment.

- The supplier shall offer a commissioning service using in-house, trained technicians and then provide a commissioning certificate.

- All products will be tested before despatch, including safety earth circuit continuity, high-voltage electrical strength testing, full circuit functionality including dimming, and checks on current drawn.

- Products and services shall be backed by a comprehensive 5-year warranty. The supplier will have an established history and financial security.

- The supplier shall demonstrate awareness of its products’ environmental impact, engaging with circular economy principles and reducing embodied carbon. This shall be shown by the adoption of CIBSE’s TM65 and TM66 frameworks and methodologies.

- The supplier shall be carbon neutral, with measurement, reduction and offsetting systems in place. This shall be proven by an independent assessment to ISO 14064-1 (Greenhouse Gas Requirements).

- The supplier will have an established plan for achieving net-zero greenhouse gas (GHG) emissions in line with the Paris Agreement on Climate Change. This will be independently verified by the Science-Based Targets initiative (SBTi).

- The supplier will have achieved an EcoVadis rating of Silver or better.

Technical support

Expert technical support and professional on-site commissioning.

The Thorlux Technical Services department is ready to answer all queries regarding Thorlux products and their use in specific environments.

The company also offers a professional on-site commissioning service to configure products to provide the desired performance and return on investment. For this service, Thorlux employs its own fully trained personnel.